KBK flexible modular workstation crane for sale:

DQCRANE KBK crane is light duty, with simple structure and limited lifting capacity, the lifting capacity from 0.125 ton to 3 ton Max., generally matched chain hoist to handling material.

KBK crane system VS traditional overhead crane:

- Reduced plant cost: The equipment does not require support from plant corbels. During plant design, the bearing capacity of columns can be minimized, significantly reducing overall plant construction costs.

- No modification to plant structure: For existing plants, the system can be installed at any time according to production requirements without altering the original plant structure.

- Less idle equipment: The coverage area can be designed precisely based on actual needs, reducing idle time and minimizing equipment waste.

- More accurate positioning: Lightweight and compact structure ensures easy operation and precise load positioning.

- Energy-saving and environmentally friendly: Low power requirement and reduced energy consumption contribute to energy efficiency and environmental protection.

- Low operating noise: Simple structure with a low failure rate significantly reduces operational noise and the impact of equipment failures.

- High overall benefit: The track system is maintenance-free, electrical components are easy to maintain, and operating costs are low. Reduced downtime and labor costs result in high overall efficiency and benefits.

KBK crane system VS other suspension overhead crane:

- High-strength steel track manufactured by cold-rolled forming, ensuring excellent rigidity and no deformation.

- Closed C-type and Ω-type track design: Effectively prevents dust accumulation, reduces trolley wheel wear, and extends service life.

- 2° inclined track design: Ensures the trolley remains centered on the track while minimizing sliding resistance.

- Wide hanging point spacing: With a specially designed track structure, the maximum hanging point distance reaches up to 9 meters, significantly reducing the number of columns and minimizing interference in the workspace, resulting in a cleaner and more aesthetic workshop layout.

- Low equipment cost: Optimized structural design reduces the need for additional steel structures, thereby significantly lowering overall costs.

- High lifting capacity: Capable of handling loads up to 3000 kg.

KBK flexible modular suspension crane system:

Series of KBK flexible modular suspension crane system contains KBK-D type monorail, KBK LD type single girder, KBK-LS double girder, KBK-DZX the pillar mounted column jib crane, KBK-BZX wall-mounted type crane, KBK-MD single-girder gantry crane, KBK-MS double girder gantry crane, KBK-DT stacking crane, KBK-JS machinery and so on all kinds of lifting equipment, lifting weight 125KG - 3000KG, have wide use range, especially suitable for modern production conveyor line, summary of its characteristics as follows:

- High reliability and stability: The KBK flexible modular suspension crane is composed of standardized modular components, ensuring consistent quality through mass production. The main structure is made of high-strength cold-rolled profiles with excellent rigidity and low dead weight, guaranteeing overall system stability.

- Excellent adaptability: The KBK modular crane system can be flexibly designed and installed according to the requirements of each workstation. It supports configurations ranging from single-point delivery to high-precision multi-point, multi-cycle automated conveyor lines and can be freely combined. The system is suitable for both new plant installations and the renovation or expansion of existing facilities.

- Easy installation, economical and efficient: The KBK system is simple to install and commission. All KBK profiles and standard modules are connected through bolted joints, enabling fast assembly and cost-effective operation.

- Space-saving and flexible operation: The KBK system reduces factory space occupation, improves operational efficiency, and supports manual, semi-automatic, and fully automatic operation modes.

Freestanding workstation crane improves productivity:

- With the rapid development of the construction industry and the increase in large-scale buildings, the demand for cranes has grown significantly.

- The KBK freestanding crane system is composed of standardized and modular components.

- According to user requirements, the system can flexibly combine straight rails, curved rails, suspension devices, trolleys, electric hoists, lifting systems, electric drive units, power supply, and control systems, making it an efficient solution for material handling operations.

How to buy KBK workstation cranes:

- Lifting capacity: ____ kg

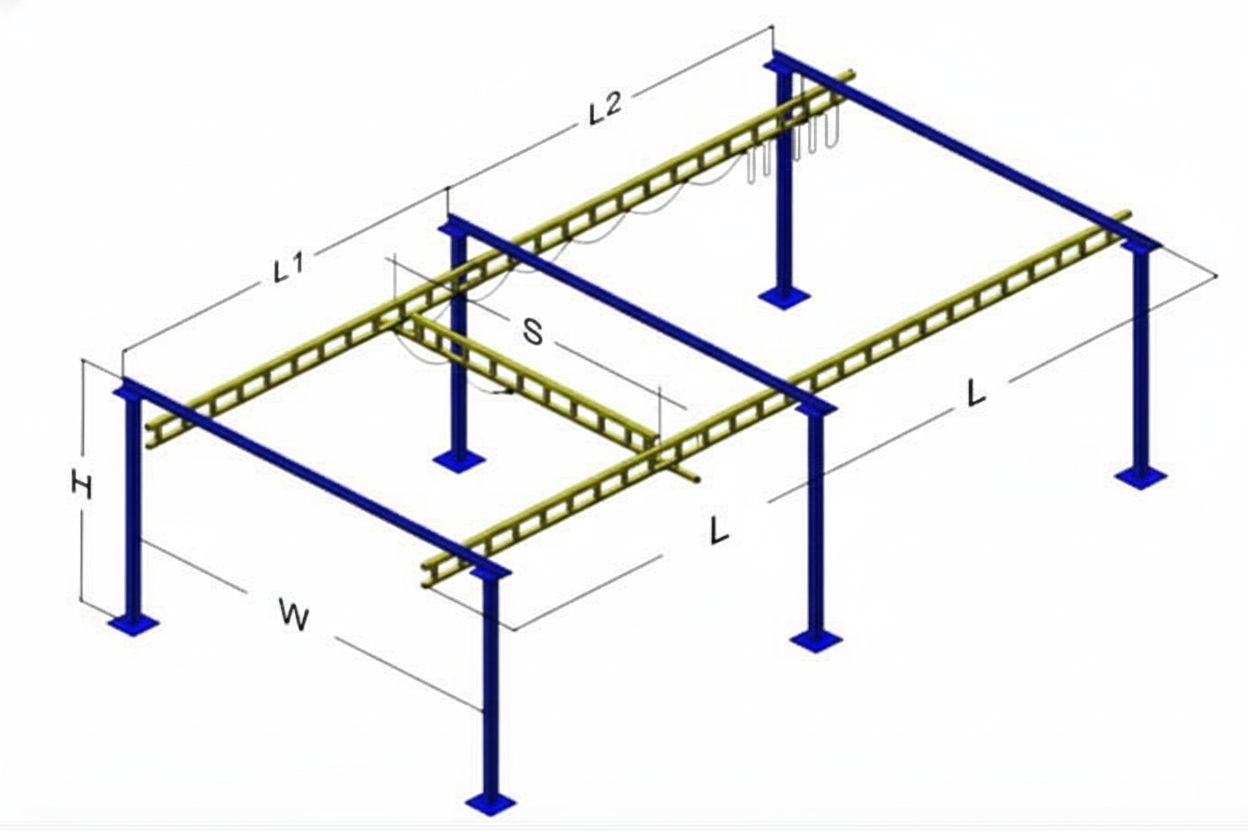

- Dimensions: W (Span) = ____ m, H (Height) = ____ m, L = ____ m, L1 = ____ m, L2 = ____ m

- Hoist type: Electric chain hoist / Wire rope hoist / Manual chain hoist

- Crane travel type: Electrical type / Manual type

- Power supply (if electrical type): ____ V / ____ Hz / ____ Phase

- Control mode: Remote control / Pendant control

- Number of KBK cranes running on the same track: ____

- Transportation: Please provide the nearest seaport name so that we can quote the shipping freight.

DQCRANE Workstation Overhead bridge cranes can be freestanding or ceiling-mounted and can be fully customized. Contact us to learn more!